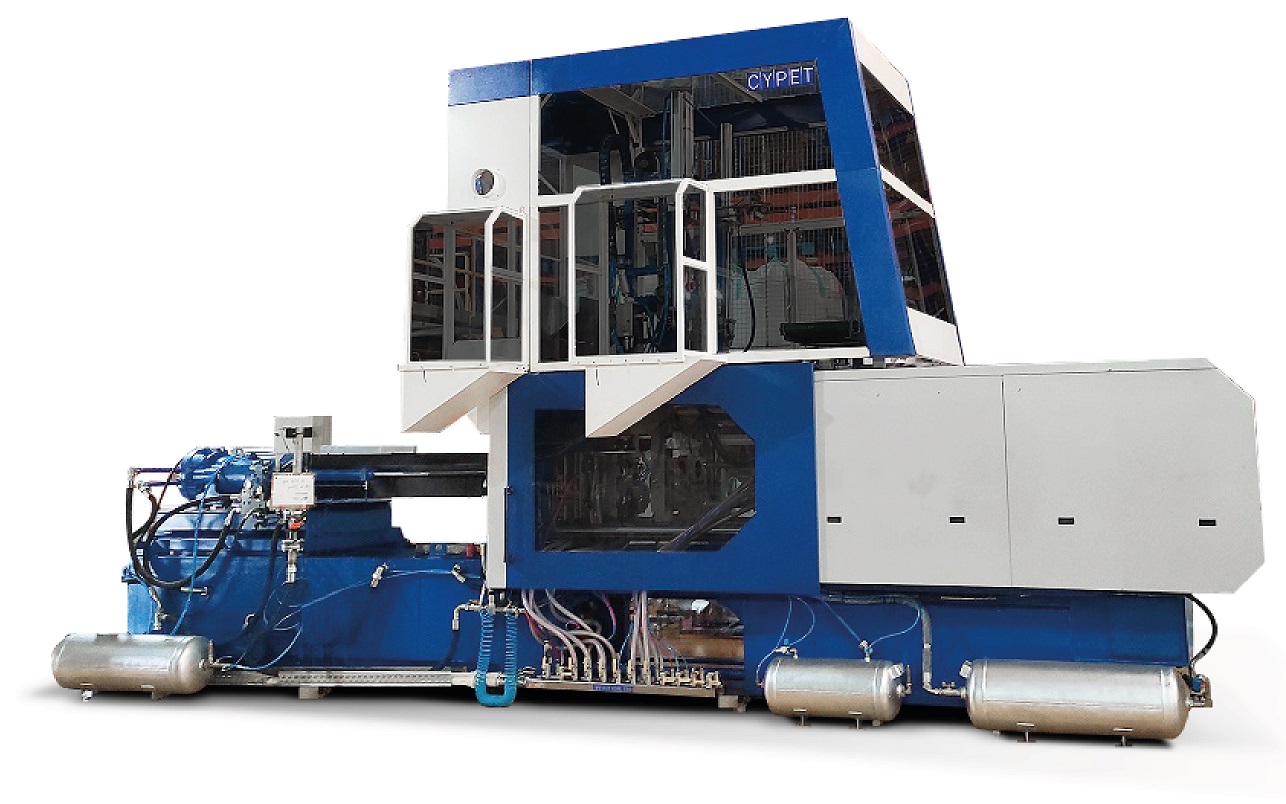

Injection Stretch Blow Molding Machines K6L, K12L, K25L, K35L/XL

Patented Single Stage PET processing System

The CYPET K6L – K35L/XL model range currently offered by CYPET, consists of fully automatic single stage injection stretch blow molding machines, capable of producing finished containers directly from PET resin. The system utilizes CYPET’s patented technology that uses only two stations, one for injection molding the PET preforms, and the second to stretch blow mold the PET containers. This range of models allows production of very small to large containers, up to 75Ltr in size, with up to 320 mm neck diameter.

Highly optimized, energy-saving servo-hydraulic technology as well as the use of an air recovery system as standard, reduces energy consumption by up to 40% (0.31kWh/kg of finished bottles). The machines have generous clamping force, large platen size and extra-long opening stroke. This allows molds with higher cavities than the toggle range machines, achieving higher output with less investment. The molds’ hot runner is naturally balanced, enabling consistent mold filling for any preform weight and valve gated to eliminate stringing. Bottle ejection occurs via free drop as standard, or optionally via an automatic take out system onto a conveyor for downstream processing.

Production Capabilities

The machines can mold different types of PET containers, such as miniatures, pharmaceuticals, personal care containers, water bottles, edible oil stackable jerrycans, wide mouth jars, pressurized containers (eg: beer kegs), drums and more. Medium sized containers (5ltr or larger), can be molded with a handle on the neck as one piece, saving the trouble of assembling an external handle.

The CYPET Long stroke machines can also be used as a standard injection molding machines for a wide range of plastic resins, further de-risking the investment in the machine and maximizing their utility.