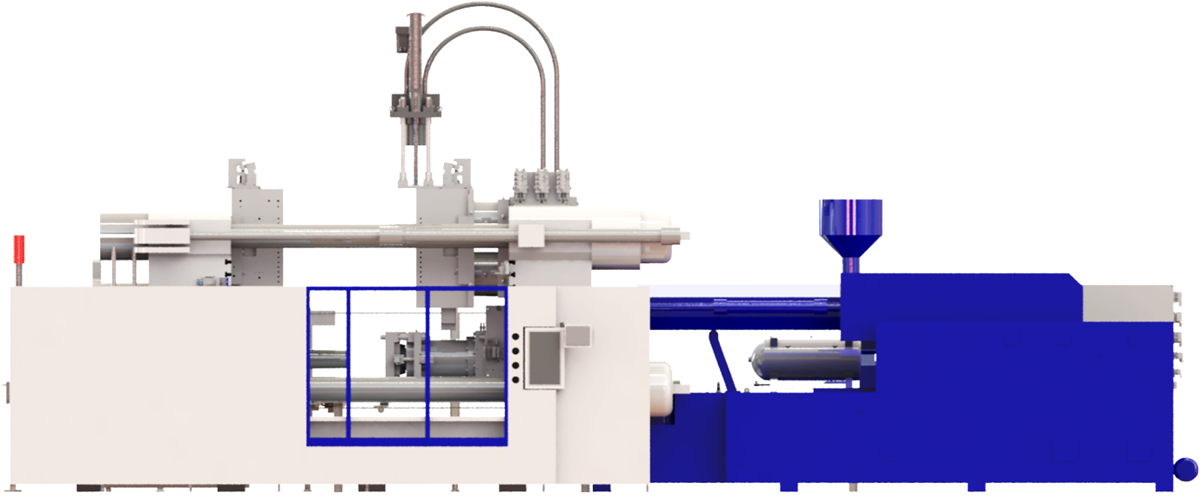

Injection Stretch Blow Molding Machines

Transform PET Resin directly into containers using the most flexible single stage PET blow molding machines. Suitable for producing bottles, jars, jerrycans, drums and rectangular containers from 20ml up to 120ltr in size.

The PRO series is the latest generation of CYPET Injection Stretch Blow Molding machines, which extend the competitiveness of 1-step blow molding, with high productivity. The main benefits for users of these machines are:

1. Fast Payback Time

2. High Productivity and Efficiency

3. Quality, Sustainability, Ease of Use

4. Supreme Flexibility – for example, 50ml to 5L on one machine

The PRO series of machines consists of 5 models, to cover a wide range of bottle & jar sizes and production outputs.

The K185 machine is a revolutionary fully automatic single stage injection stretch blow molding machine, able to produce PET containers up to 1000L in size directly from PET resin. The system utilizes CYPET’s patented technology where a single clamping unit operates both the injection mold and the blow mold, with robots handling the transfer of PET preforms from one mold to the next. PET packaging can now enter new markets, such as water tanks, large drums and IBCs – at a fraction (up to 50%) of the weight and cost. There is a huge sustainability benefit from the significant reduction in plastic consumption used for each container as well as the 100% recyclability of PET that will be brought to the large container market.

The CYPET K Series machines are fully automatic single stage injection stretch blow molding machines, capable of producing finished containers directly from PET resin. They utilize CYPET’s patented technology that uses only two stations, one for injection molding the PET preforms, and the second to stretch blow mold the PET containers. The K Series machines are designed to minimize floor space and provide unparalleled flexibility. The K model range can produce containers ranging from 20ml up to 120Ltr, with up to 400 mm neck diameter and is ideal for low volume production applications.

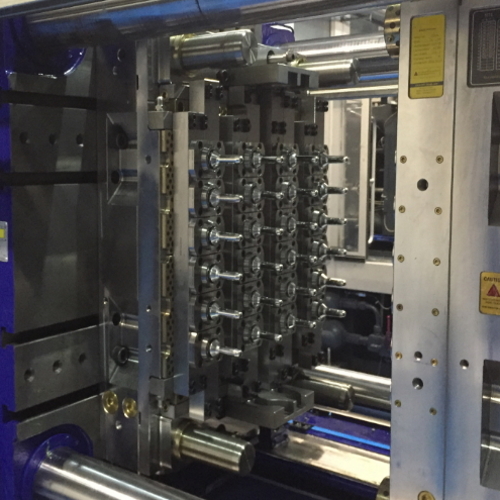

Injection and Blow Molds

CYPET molds are designed and optimized to produce the best quality container in the most economical way. Our molds are based on the two stage technology and made from high grade stainless steel. To ensure high-quality end products, CYPET injection molds are equipped with naturally balanced, valve gated hot runner with top quality components for easy maintenance.

Auxiliaries

The Injection Stretch Blow Molding process requires a range of Auxiliary equipment to ensure ideal conditions for PET container production. These include:

- Resin Dryer

- Water Chiller

- Mold sweat dehumidifier

- Air compressors/boosters

- Compressed air tanks

- Mold temperature controller

CYPET can supply the full suite of required machinery or can advise on the correct characteristics for direct purchasing from a list of recommended suppliers.

Auxiliaries

The Injection Stretch Blow Molding process requires a range of Auxiliary equipment to ensure ideal conditions for PET container production. These include:

- Resin Dryer

- Water Chiller

- Mold sweat dehumidifier

- Air compressors/boosters

- Compressed air tanks

- Mold temperature controller

CYPET can supply the full suite of required machinery or can advise on the correct characteristics for direct purchasing from a list of recommended suppliers.

PET Preform Production Systems

Utilising the extensive knowledge and experience developed for single stage bottle production, CYPET offers turn-key production systems for PET preform production.

We optimise the technical specifications of machine, moulds and auxiliary equipment for fast cycle times and high preform quality.

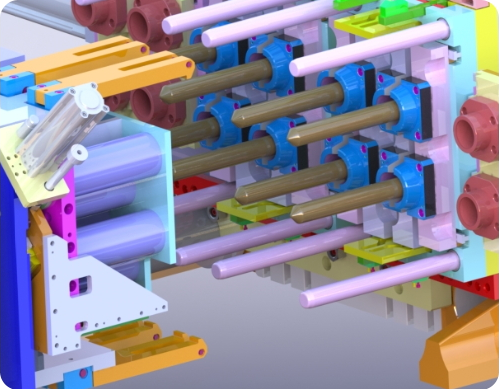

Preform Post Cooling Systems

Utilise CYPET’s patented post cooling systems for fast cycle times and improved quality, suitable for large, thick preforms. After cooling in the mould, the preforms are additionally cooled for 1 extra cycle on the injection cores and further cooled for an additional 4 extra cycles in cooling tubes.

Preform Post Cooling Systems

Utilise CYPET’s patented post cooling systems for fast cycle times and improved quality, suitable for large, thick preforms. After cooling in the mould, the preforms are additionally cooled for 1 extra cycle on the injection cores and further cooled for an additional 4 extra cycles in cooling tubes.