CYPET Technologies offers a complete range of product development services to help customers develop the next generation of PET containers with minimum cost and maximum confidence.

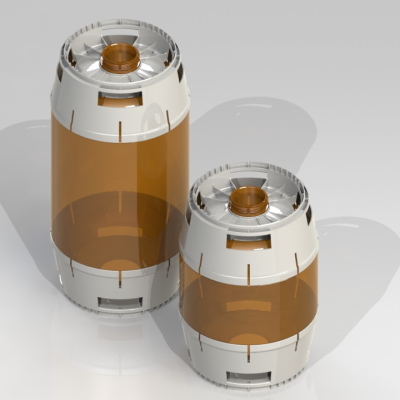

Container Design

Our experienced design team has designed some of the most stunning containers in the PET plastics industry.

Using state of the art software, we can bring shape to your ideas and function to your requirements.

Go from concept design to detailed specification drawings in a matter of days, knowing the bottle design will be second to none, while still respecting the limitations of PET processing.

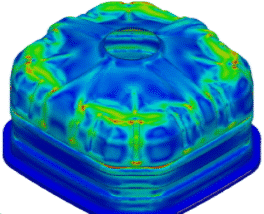

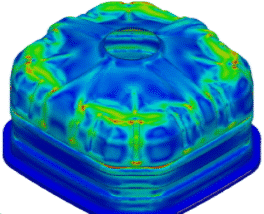

Container Strength Optimisation

An essential part of product development is optimisation of the shape of the container to achieve the lightest weight that can be strong enough to prevent failure during its life cycle.

Our experience in modelling and simulation of the typical worst case scenarios that a container may see during its lifetime (Top Load, Drop Test, Vacuum, Positive Pressure), can help get to the best shape to maximise its mechanical performance.

Avoid the costs of mould re-machining and re-testing by getting the shape right from the beginning.

Container Strength Optimisation

An essential part of product development is optimisation of the shape of the container to achieve the lightest weight that can be strong enough to prevent failure during its life cycle.

Our experience in modelling and simulation of the typical worst case scenarios that a container may see during its lifetime (Top Load, Drop Test, Vacuum, Positive Pressure), can help get to the best shape to maximise its mechanical performance.

Avoid the costs of mould re-machining and re-testing by getting the shape right from the beginning.

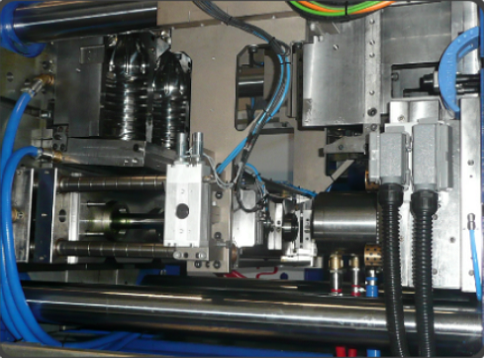

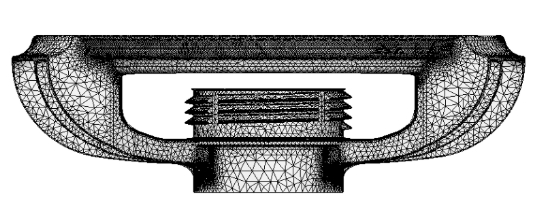

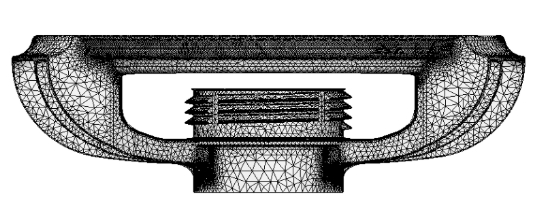

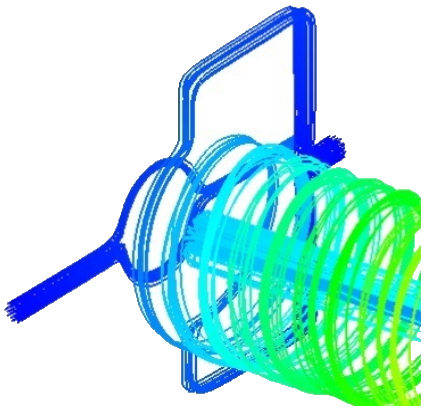

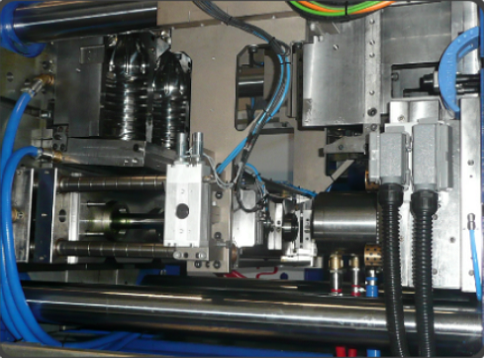

Injection Mould Design & Development

Utilise CYPET’s powerful software tools and simulations experience to improve the performance of your injection moulds and achieve high quality injection moulded parts.

We offer the following services:

- Hot Runner Rheological Balancing Studies

- Hot Runner Thermal Balancing Studies

- Mould Cooling Analysis and Optimisation

- Mould Structural Analysis and Optimisation

Pilot Moulding & Production

Introducing a new container in the market can be a daunting task, especially if investments in new tooling or machinery are needed up front.

Additionally, there are numerous technical feasibility risks as well as commercial risks (market acceptance) that need to be managed for new products entering the market.

CYPET offers Pilot Moulding & Production services to enable customers to minimise technical risks as well as test their market with new product samples before investing in new moulds and machinery.

Pilot Moulding & Production

Introducing a new container in the market can be a daunting task, especially if investments in new tooling or machinery are needed up front.

Additionally, there are numerous technical feasibility risks as well as commercial risks (market acceptance) that need to be managed for new products entering the market.

CYPET offers Pilot Moulding & Production services to enable customers to minimise technical risks as well as test their market with new product samples before investing in new moulds and machinery.