CYPET PRO Series

The PRO series is the latest generation of CYPET Injection Stretch Blow Molding machines, which extend the competitiveness of 1-step blow molding, with high productivity.

Why the PRO Series?

1. Fast Payback: The PRO Series enables a faster return on investment, with payback time of around 1.5 to 2 years.

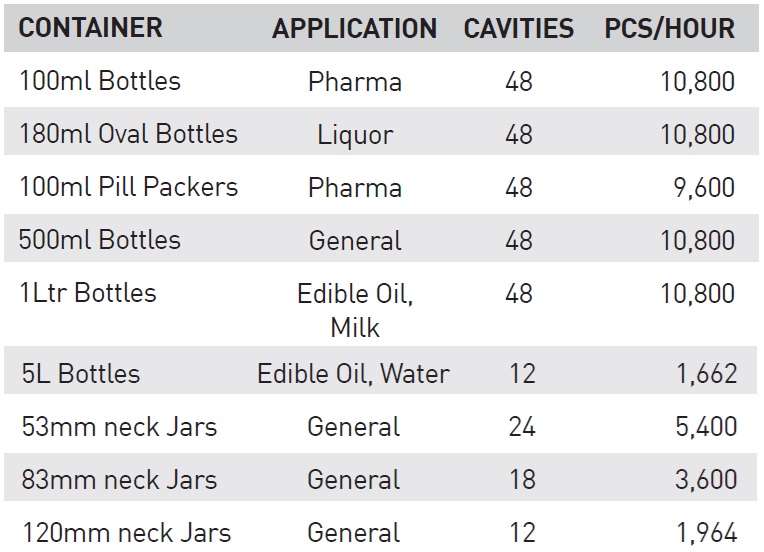

2. High Productivity and Efficiency: Our 1-step PRO systems combine the process of injection, partial cooling, conditioning, and stretch-blowing into one efficient machine, significantly reducing energy consumption and production costs compared to the traditional 2-step process, while achieving outputs up to 11 000 bottles per hour.

3. Quality, Sustainability, Ease of Use: With precise temperature control along the length of the preform but also around its perimeter, the PRO machines ensure higher bottle quality with opportunities for light weighting, reducing cost of production and improving sustainability. It also allows easier processing, maintenance and mold changeover compared to other single stage machines.

4. Supreme Flexibility: The PRO Series offers unprecedented adaptability, capable of producing bottles and jars ranging from 20ml to 50L. You can produce a broader range of products with one machine, or even use it for injection molding caps and preforms to avoid under-utilization. Bottles come out of the machine on a conveyor belt, making it easy to connect the machine to subsequent post processing stations.